A versatile range of robust in-line options are available to enable fully automated job production and produce professionally finished, high-quality documents that command a premium price in the market.

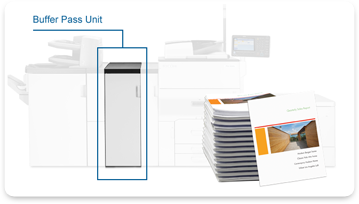

The Buffer Pass Unit minimizes toner blocking on stacked, coated paper by cooling output prior to the media entering a finishing unit.

The Paper Decurl Unit is ideal for commercial printers who frequently produce jobs with high toner coverage on thin paper and paper with long grain, as it significantly reduces the natural curl that can occur, delivering sheets with optimal flatness.

Configure the system with either a Single Source or Dual Source Cover Interposer to easily feed pre-printed covers and inserts into the finishing workflow at the touch of a singular button.

The CI4010 Single Source Cover Interposer is compatible with the SR4090 and SR4100 3,000-Sheet Finishers. The CI4020 Dual Source Cover Interposer is compatible with the SR4110 2,000-Sheet Booklet Maker.

When the system is configured with a GBC StreamPunch Pro, printing, punching and collating is combined into one easy step, eliminating labor-intensive offline manual punch operations and reducing the costly errors that can arise. It is an ideal finishing solution for production environments that produce bound books in a variety of styles on a regular basis. The interchangeable die punch unit rapidly produces punched documents for a variety of binding styles including traditional two and three-hole punching, ProClick®, WireBind™, CombBind™, VeloBind® and ColorCoil™.

The versatile FD4000 Multi-Fold Finisher offers six professional folding patterns to accommodate virtually any folding need completely inline: Half-fold, Double Parallel, Gatefold, Z-fold, Letter Fold-in and Letter Fold-out. Ideal for the production of newsletters, brochures, pamphlets, direct mail, marketing collateral and promotional materials.

The SR4090 3,000-Sheet Finisher offers 65-sheet stapling and the SR4110 offers 100-sheet stapling. Both offer the ability to output 13" x 19.2" paper sizes and have an optional hole-punch unit.

The SR4100 2,000-Sheet Booklet Finisher allows documents to be professionally finished as paginated, duplexed, saddle-stitched, and folded booklets. It provides three destinations for output, includes hole-punching capabilities and, with the 2,000-sheet Shift Tray capacity, can be left unattended during long runs, contributing to an overall increase in productivity.

When the system is configured with the BK5010e Production Booklet Maker the result is a fully integrated system that produces saddle-stitched booklets up to 30 sheets at a time, the equivalent of a 120-page book. The finisher automatically adjusts for paper size and direction and offers a variety of drivers, making printing from any network seamless and easy.

The BK5010e is available with the following options:

Explore this module to learn more about the system's key features, functions and professional finishing options.

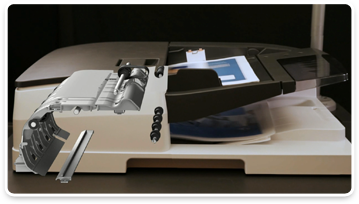

The newly designed 100-sheet ADF with duplexing capabilities quickly captures hardcopy originals for copying, editing, storing or electronic distribution. The system scans stacks of mixed originals over 200ipm in duplex mode.

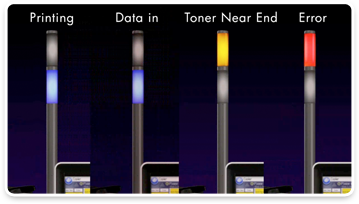

The elevated status light is visible from long distance and any direction so users can monitor printer status in real time. If a change in status should occur, operators are automatically alerted that attention is needed.

The newly designed full-color WVGA articulating Control Panel displays easy-to-identify, vivid icons for quick and easy navigation. The articulating arm allows users to reposition the panel for optimal viewing. Users can also access the Paper Library and scan to the SD Card and USB slots directly from the panel.

New PxP-EQ toner spreads evenly across the page, allowing the toner to absorb light more efficiently and reflect more vibrant, consistent color, increasing color intensity by 10%. Operators can also replace toner cartridges on the fly, decreasing downtime and increasing productivity.

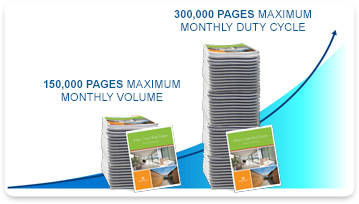

The main unit of the Pro C5100s/C5110s is made from Electric Furnance Steel Sheets which contribute to the unit's environmental features. Powered by a 320GB hard disk drive, this heavy-duty engine provides 1200 x 4800dpi imaging quality, speeds up to 80ppm and media support for 300gsm. With a maximum volume of 150,000 pages-per-month and monthly duty cycle of 300,000 pages, this reliable machine can be counted on day in and day out.

The compact design of the Pro C5100s/C5110s is ideal for organizations where space is limited. It features the smallest footprint in Ricoh's production lineup and requires less than 4 inches of clearance from the wall.

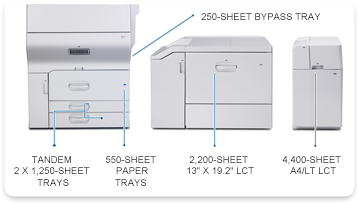

With a standard paper capacity of 3,850 sheets and a maximum capacity of 8,250 sheets, the Pro C5100s/C5110s helps keep workflow steady and enables long print runs without interruption.

All front-loading paper trays feature an LED light indicating which tray is in use. This allows users to easily refill another paper tray while the unit is still in operation.

Trained users can replace up to twelve key imaging components including the Fuser Unit and Feed Rollers, keeping the system performing at peak efficiency and ensuring jobs are delivered as scheduled.

The Waste Toner Bottle can be removed on the fly by a system operator. It does not require a service technician to be called or for the suspension of the printing process.

The Paper Decurl Unit reduces the natural curl that can occur when printing high toner coverage on thin paper and paper with long grain.

The optional Buffer Pass Unit helps minimize toner blocking on stacks of coated paper by cooling output prior to the media entering the finishing unit.

The Pro C5100s Series offers eight finisher options which allow for a large variety of output and finished product, including newsletters, brochures and perfect-bound, saddle-stitch and spiral-bound books. (Configuration shown with Dual Source cover interposer + 3,000-sheet finisher with 100-sheet stapling.)

With more demand for print jobs on larger media, the Pro C5100s/C5110s allows 13" x 19.2" sized media to be loaded directly in the mainframe. The system also supports specialty stocks and paper weights up to 300gsm; thick stocks up to 256gsm can be duplexed with ease. New transfer technology enables higher transfer quality onto textured surfaces.